Joseph Coupal - Monday, June 22, 2020

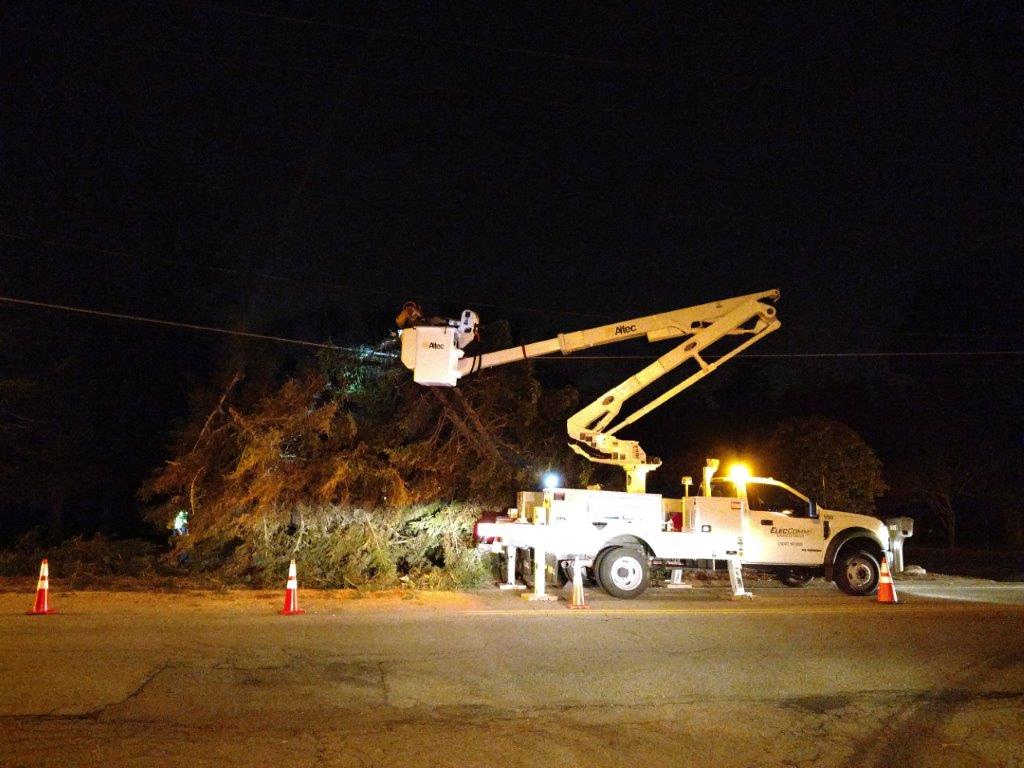

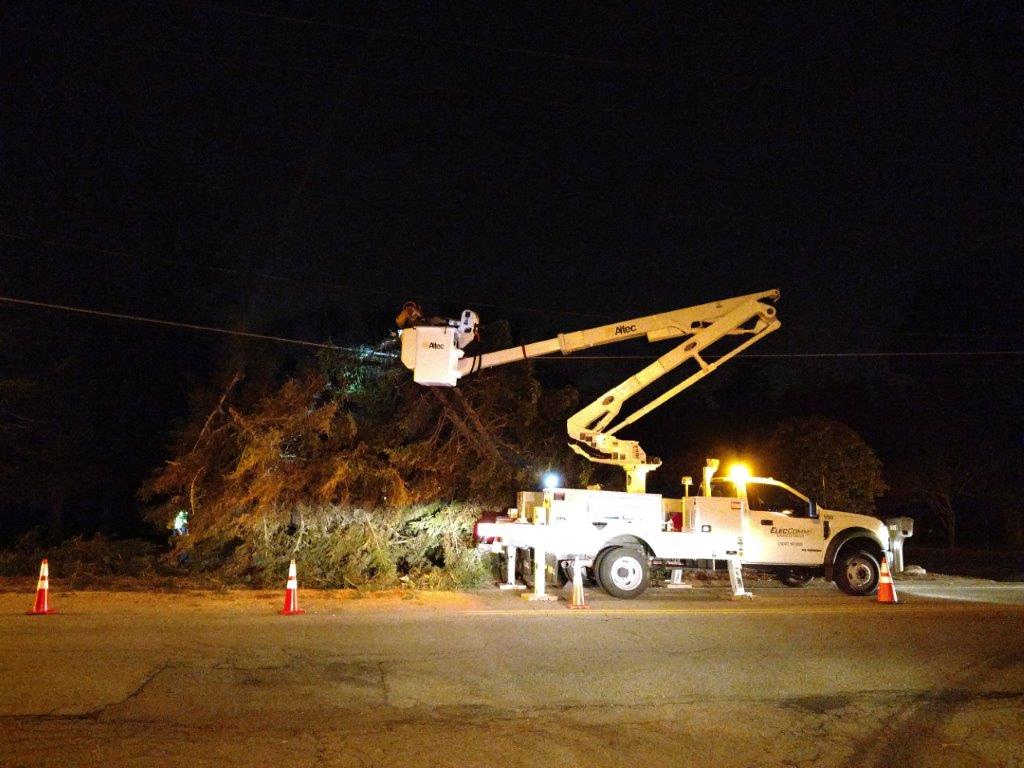

Severe storms and their associated threats to power distribution services can occur at any time. Weather disturbances are a constant threat to overhead power lines. This blog is simply to remind that ETS Storm Service is a dependable stalwart in rapid response and power restoration services across New England.

Our certified electrical engineers and technicians are equipped with a fleet of repair vehicles that are ready, equipped, and always maintained to rapidly respond. We deliver on-site dielectric, critical repair and inspection testing labs for line equipment of all sizes and power loads.

ETS Inc’s highly trained inspectors deploy upper and lower boom trucks, buckets, and liners that are all electronically insulated meeting ANSI 92.2 Standards. In addition to rapid response emergency support services, ETS provides preventative maintenance services as well. We provide annual full-service inspection, repair and testing services which includes Dielectric Testing (up to 100kv), Hot-line tools & Gas Detection Monitors in various industries. Headquartered in Wilmington, Massachusetts, ETS Inc. serves the New England area including Connecticut, Rhode Island, Massachusetts, New Hampshire, Vermont and Maine.

For more information about our services, contact ETS Inspection Testing and Repair.

Joseph Coupal - Thursday, June 18, 2020

Golf netting systems function as a protection to keep golf balls inside the field and prevent accidents and damage to neighboring properties. ElecComm is a dynamic company that leverages our skill sets and equipment fleet to expand beyond our electrical service specialty. In fact, we offer the highest quality golf netting solutions in and around the greater Boston area.

Benefits of Having a Durable Gold Netting System

- Legal Obligation. As a golf course operator, you are obliged to set-up a sturdy and stable golf range netting to ensure the safety of the spectators as well the properties adjacent to the golf field. When legal safety standards have been breached due to errant balls, the operators are liable and can be charged with legal penalties.

- Safety. Golf nets protect players and spectators from injury related to stray balls. As well, people passing by near your golf course.

- Protection of Property. Whether your building or your neighbor's, the golf barrier netting makes sure that golf balls won't hit and damage properties by keeping them within the driving range.

- Separates The Perimeter. Golf netting system acts as a divider that separates the golf play area from other fields or courts intended for other sports.

Since each golf course is unique, each demands a tailored golf netting system plan. Thus, it is smart to contact ElecComm to help you figure out the perfect design according to your location and natural elements that can affect the installation of your golf netting system.

Joseph Coupal - Friday, June 12, 2020

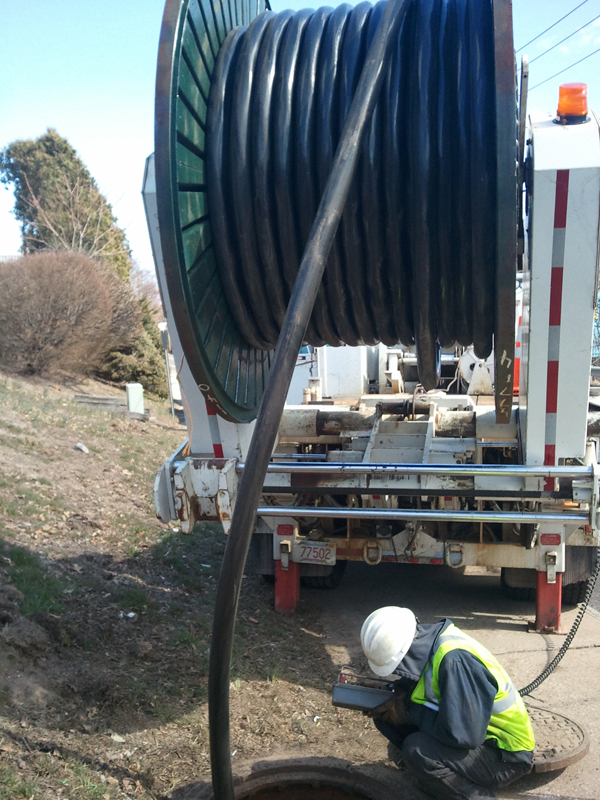

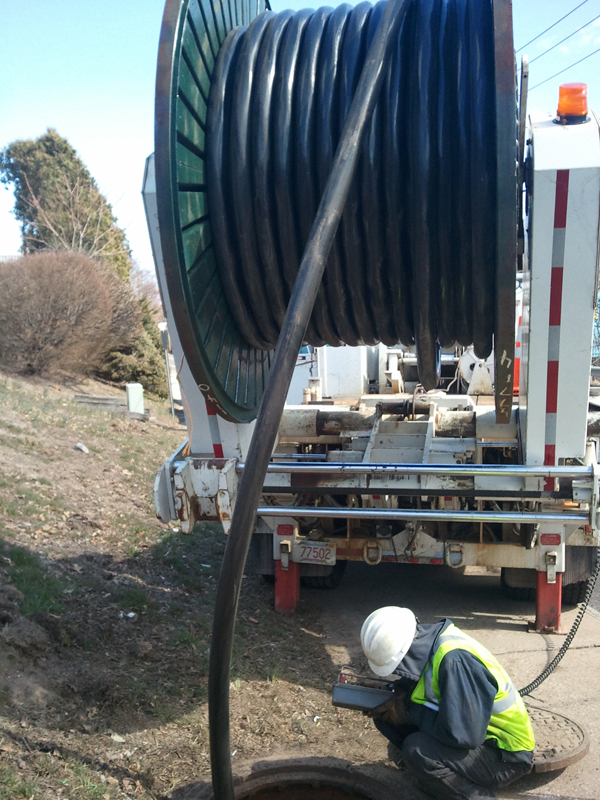

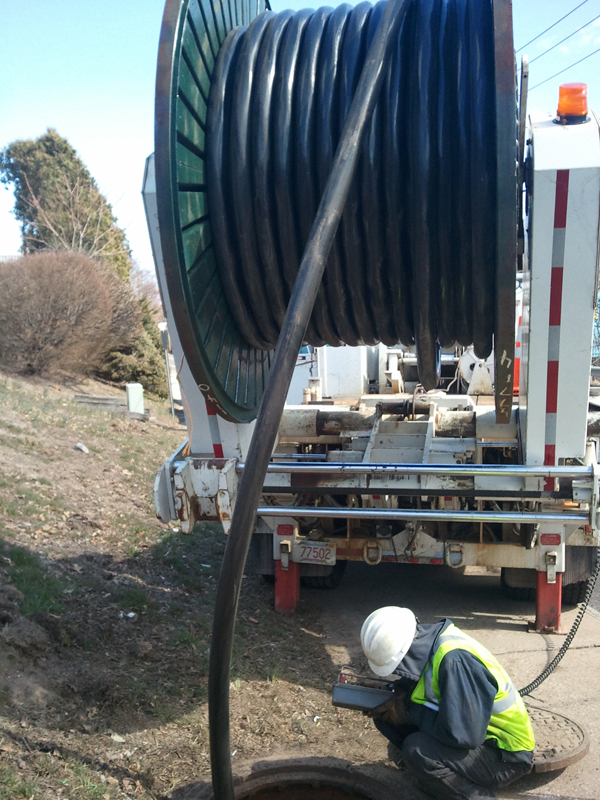

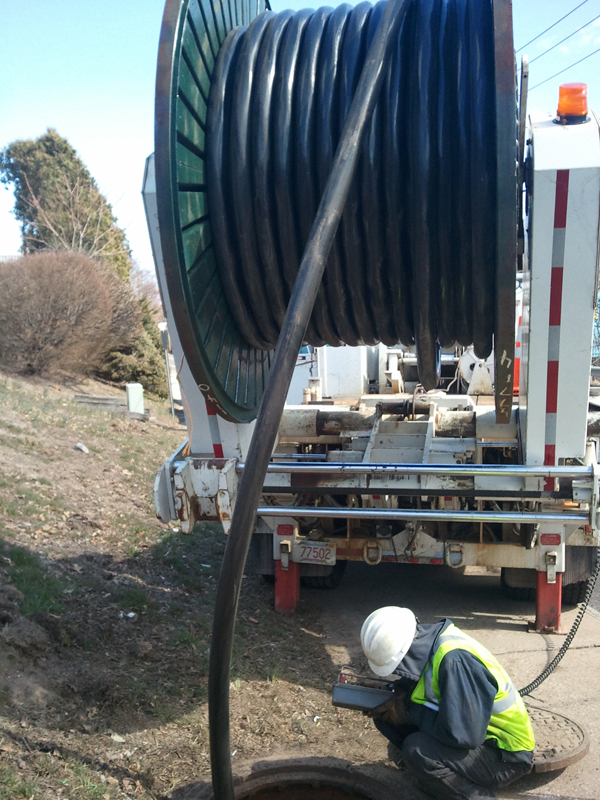

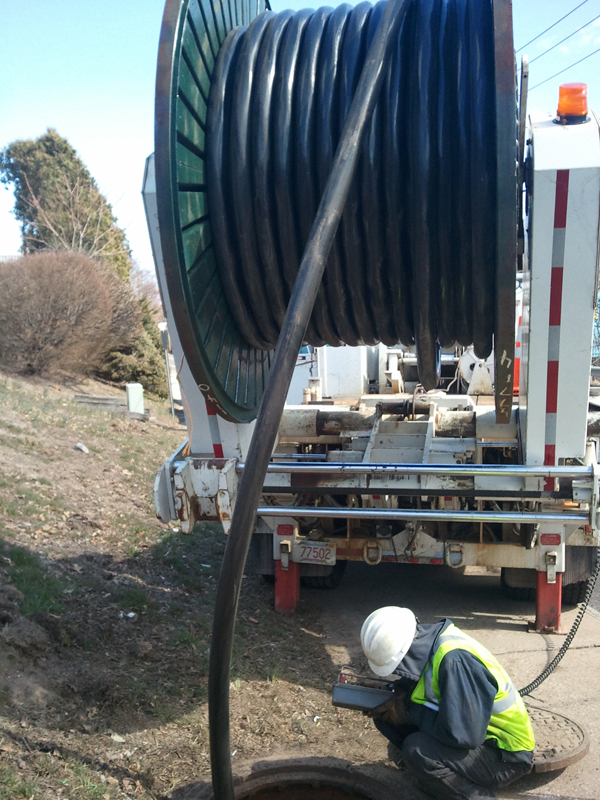

During excavation it is of utmost importance to take all the preventative actions before commencing work as outlined in the Code of Practice. One of the main dangers when digging without prior preparation is the possibility of injury from underground power cables. During digging anything in contact with live electricity cables can lead to injuries that can be fatal.

The risk of the explosive effect of arcing current and subsequent fire simply must be professionally addressed. With a slight point of a tool or when the cable is crushed severely enough to cause contact between the sheathing and one or more conductors will trigger fires or explosions.

When installing and/or maintaining any underground electrical system, it is of paramount importance to be equipped with the correct cabling map in order to know the location of power cables. We are subject matter experts in cable mapping. If the cable system is not mapped and documented at the start of our support project, it will be by project’s end. It is vital to maintain cable records and have them stored in a visible area inside your office for emergency purposes. These records provide instant definition of the essential cable voltages and the knowledgeable person on site who knows how to interpret the plans. This documentation will assist future operations and maintenance process that involve underground cable survey analysis services.

Realize that in many cases, high voltage powers cables are oil filled. When accidentally violated they are subject to flash ignition. The resulting flash electrical fire can spread to other nearby services such as gas pipes etc. Such accidents are caused by failure to take all relatively safety precautions to prevent accidental contact with underground services.

We exist to help you to install, manage, maintain, and monitor high voltage underground cabling systems affordably and effectively. For information on how to get started, contact us.

Joseph Coupal - Thursday, June 11, 2020

Dielectric testing services are an important measure to improve the quality and control of insulating conductors and electronic parts. There are a number of dielectric testing techniques and services to choose from. Performing the appropriate measurement will ensure accurate results

Coaxial Probe – When testing for the permittivity of a material, coaxial probe is the proper technique. This is done by pressing a metallic probe against the material or soaked in a liquid solution to gauge reflection coefficient that verifies the permittivity. This simple approach allows the user to gather data across a broad range of frequencies.

Transmission Line – This method involves putting a sample on a waveguide. Next, assess intricate scattering parameters using a VNA analyzer. It applies both reflection and transmission to collect measurements with greater sensitivity than the coaxial approach.

Free Space – Free space can test electricity over a diverse range of frequencies. This is performed by placing large, flat samples of materials under extreme heat and in a hostile setting for a dielectric testing. This method allows you to get reflection and transmission coefficients without any contact. Moreover, it enables you to evaluate both electrical and magnetic properties of the material.

Resonant Cavity – This technique gathers measurements with high accuracy and high-temperature support. It enables you to get accurate data with dielectric loss materials. The method applies the concept of a resonant frequency shift of a tuned cavity when a loss material acts as a resonator.

Parallel Plate - In this method, the tester needs to sandwich the dielectric item between two electrodes to create a capacitor. Then, using an LCR meter or impedance analyzer measurements are collected along with a dielectric test fixture. This is the preferred dielectric technique for testing low frequency materials.

Planar Transmission Line - This method uses a microstrip line to test materials in RF and microwave components. It is appropriate for industrial purposes due to its compact feature. In this testing approach, dielectric measurements are inferred from a shift in permittivity using appropriate expressions.

If you need dielectric testing service, contact ETS Inspection and Testing Services.

Joseph Coupal - Sunday, May 31, 2020

When June arrives, so does severe thunderstorm and hurricane season. While summer weather is bright and warm, it can turn nasty and without warning. Severe storms and hurricanes can form anytime within June to November. This always pose a threat to overhead power lines as storms bring forth heavy rain and strong winds that can uproot and knock down trees. Falling trees can be caught in pole lines eventually causing cables to snap resulting to widespread power failure.

In worst case scenarios, know that Eleccomm's emergency storm response is dedicated to assist major public utilities throughout the Northeast restoring power during major power outages resulting from storms. In addition, ElecComm (ECC) has expanded the overhead segment of its business to include, the everyday, installation, removal and maintenance of overhead lines. Moreover, we recommend upgrade of obsolete electrical infrastructures ahead of any predicted tropical cyclones for a sturdier electrical system framework. This will ensure continuous stream of electricity in your business facility amidst weather disturbances.

Know that our team is fully crossed trained and is ready for dispatch in preparation for any planned or unplanned event. Contact ElecComm for emergency power restoration, installation and maintenance of new infrastructures.

Joseph Coupal - Thursday, May 28, 2020

We’re proud of the fact that across the greater Boston area and beyond, we’re replacing old, unsightly, and increasingly vulnerable above ground high voltage cabling systems with state of the art Underground cables. The exquisite beauty of Boston really shines through in the areas that we’ve improved with this service.

Underground cabling empower municipalities and developmental communities to highlight their unique beauty without tangled poles and wires in the way. You’ve all seen the landscapes that are overpowered by unsightly utility wires and accessories. We’re helping Boston move on from those dated and costly technologies.

Whether you’re a municipality civil engineering planner or a commercial real estate developer, we’ve been assisting you for decades now with underground high voltage cable installation services here in Boston. Contact us here at ElecComm, the region’s most trusted underground cable installation and maintenance service provider.

Joseph Coupal - Thursday, May 28, 2020

Personal protective equipment and live-line tools require regular upkeep as they help minimize high-voltage accidents and liability when working with live electrical poles and components. Since the safety of your team is a top priority, routine dielectric testing program should be scheduled and prioritized for safety, regulatory, and for equipment preventative maintenance.

If you own one or more aerial lift vehicles, ETS will provide full-service testing and repairs as necessary to pass certification & testing. We are accomplished at minimizing equipment downtown, ensure safety of all your equipment and maximize cost savings. Our services range from minor cleaning and preventative maintenance to a full refurbishment.

ETS, Inc. has a mobile fleet department that can meet clients on-site or any field location around New England. Have a hydraulic leak? No problem, just contact us and we will be onsite to repair.

Joseph Coupal - Thursday, May 14, 2020

When laying underground high voltage cable systems, one must understand the criticality of cold shrink and heat shrink tubing. These tubing are used for splicing, terminating and serves as an environmental seal on LV (Low-Voltage) and MV (Medium-Voltage) cables. These two types of tubes look similar on the outside but have different internal characteristics. They have different applications, installation techniques and physical properties.

Heat-Shrink Tubing is a pre-stretched shrinkable plastic tube that requires a heat source during installation. It contains a polyolefin material that is contracted to form an environmental seal protection to the joint or cable. It is ideal for industrial or commercial projects that require a chemical-resistant tubing and when serving low temperature environments.

Cold-Shrink Tubing is a factory-expanded rubber sleeve with an open end and assembled onto a supporting removable plastic core. Cold shrink tubing is installed by applying a gentle unwinding motion to release it from the core. It offers a quicker and safer installation process as compared to heat shrink tubing installation.

Cold shrink tubing is the preferred material for insulating wires, terminals, joints and connections in electrical work. You may also use it when repairing bundle of wires together and as a protection for small wires from minor abrasion. It requires to be stored in a controlled setting wherein temperature does not go beyond 43 degrees Celsius.

Both heat-shrink and cold-shrink splicing is an important step to protect spliced cables from environmental elements that may ingress within. It is an essential part of distribution circuits and DSS line re-conductoring for capacity works.

For more information about underground high or low voltage installation, contact ElecComm.

Joseph Coupal - Thursday, May 14, 2020

It difficult enough to manage and maintain a single cherry picker or a bucket truck. They are complicated machinery. But it's an entirely different story when you own and maintain a fleet of specialized equipment. Time and time again we see business owners suffer catastrophic and costly equipment failure due to both lack of maintenance attention and improper self-help maintenance practices. This is why we are introducing to you today ETS Fleet Maintenance Solutions for Boston area business owners. For decades now we’ve helped keep Boston business owners and their equipment operating at peak efficiency.

ETS offers comprehensive inspection and maintenance of aerial lifts, cranes, diggers and bridge inspection equipment. We strictly follow inspection guidelines and regulations invoked by ANSI and OHSA. Our team of certified technicians perform complete factory-specified service which covers every important component of the unit including visual inspection for worn out parts, filter cleaning, lubrication and tightening of torque with fasteners. Our technicians will also execute calibration testing and necessary adjustments to ensure ease in operation.

As per ANSI and OSHA standard, some specific fleets such as bucket trucks, digger derricks, cranes, cherry pickers, etc. requires frequent and periodic inspections. Compliance for this guidelines are considered mandatory. So if you need aerial lift fleet service, contact ETS Inspection and Testing Services. We perform fleet inspection and repairs.

Joseph Coupal - Thursday, May 07, 2020

When your golf course’s nets wear out (which they will), and your poles succumb to mother nature and scream to be replaced, you need to act for the safety and professional appearance of your course. If your building a new course, the netting service and product that you choose makes a huge impact on both the appearance and longevity of your investment. For decades now, northeast golf course managers have trusted ElecComm to install new, repair, and upgrade golf netting systems.

A sturdy and effective netting system is mandatory to ensure the safety of the people and personal property that exist and operate near your course’s protected boundaries. Worn systems can and will result in damaged property, injury, insurance claims, and increased insurance cost as a result. Don’t let that happen to you. Our full-service delivery includes ball trajectory studies, custom netting designs, and installation options customized to your budget and operational need.

Contact ElecComm for any and all golf course safety system questions and service requirements.

Joseph Coupal - Thursday, April 30, 2020

Boston (and surrounding municipalities) are expanding and upgrading their high voltage underground cabling system at a record pace and we are proud to be part of that effort. In fact, we’ve been providing underground high voltage cable installation and maintenance across the northeast for decades now. When it comes time to laydown new or maintain/upgrade existing cable in your area, only trust the proven professionals like us here at ElecComm.

We deliver the latest in underground high voltage cable technology to include real-time monitoring capability along with strategies for simplifying the operations and maintenance aspect of your cabling system. We utilize the latest burial and jointing techniques that ensure your underground cable projects are completed on time, every time, and on budget. We employ trenchless burial techniques and directional drilling that limit adjacent property disruption to the maximum extent physically possible.

We’ll beautify your city, county, town, or developmental projects with the most low-profile power distribution systems available on the market today. For more tips on underground cables, contact ElecComm.

Joseph Coupal - Thursday, April 30, 2020

Overheating is a common issue encountered within hydraulic equipment. And we know from experience that the overheating situation will shut down the exact wrong piece of your equipment at exactly the wrong time. We specialize in putting you, your business and your equipment back to work ASAP via rapid response deployment of our team of certified hydraulic repair technicians.

Whenever you encounter overheating issues within your hydraulic system, keep in mind that there are two ways to solve the problem. The first thing to do is to shut down the machinery and take a moment to think through the issue and eliminate the immediate threat of permanent damage to your equipment. You then must be able to restart the equipment with either a lower heat producing load or improved dissipation of heat. Maybe you can self-help this.

First thing to do is to inspect the fluid level of the reservoir. When it is low than the recommended level, refill it to reach the right level since hydraulic system eliminate heat through the reservoir. Make sure there are no accumulation of dirt that is blocking the airflow. Then, investigate the core of the heat exchanger and make sure there's no obstruction since its ability to remove the heat is reliant on the flow rate, hydraulic temperature and the cooling air or water that is flowing within the exchanger. You may also need to replace the cooling circuit parts if it is not working well.

Check how heat exchange perform by using an infrared thermometer as long as you know the actual flow rate of the hydraulic fluid in the exchanger. Check also the temperature of the oil that is coming in and out the exchanger and substitute the values applying a formula provided by a certified hydraulic company. A decreasing pressure will result to heat production. If internal leakage is present in any of the system parts, it will boost the heat load on the system, causing it to heat up excessively. There are multiple rationale behind this occurrence which includes a leaky cylinder draining a high-pressure fluid over its piston seal to a relief valve that was not properly adjusted.

Consequently, you need to change any of the heat generating parts that is worn out, and there are instances when a professional technician is required to figure out the component that is inflicting the issue. Regardless of the cause behind an overheating hydraulic system, it is imperative to turn it off immediately to get to the bottom of cause and mend it. Persisting to run it at inappropriate temperature is unsafe and will surely damage your equipment. It's important to be proactive when you notice an overheating system. Find the cause right away in order to address the problem.

Or, simply trust the professionals like use here at ETS. We’ll simplify your life, make sure your equipment is repaired in the shortest time possible, and put you and your equipment back in business. When you need certified technicians for a hydraulic repair, contact ETS Inspection and Testing Services.

Joseph Coupal - Sunday, April 26, 2020

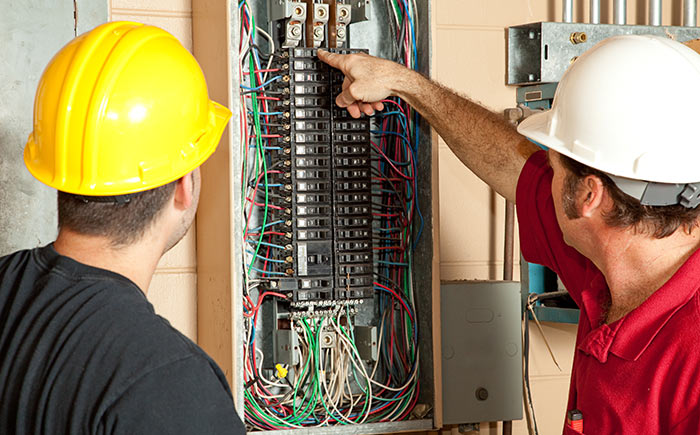

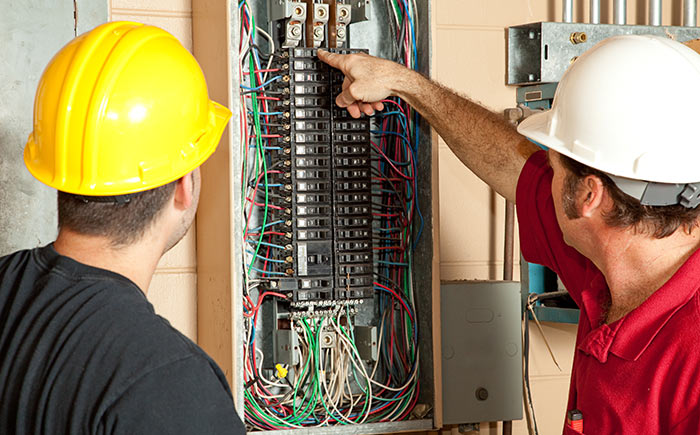

Commercial establishments require specialized electrical mechanism to prevent fires, system malfunctions, risking lives and properties. Everyone is exposed to electrical hazards, but shocks and burns from faulty wiring at any business establishments can result in horrific consequence. Circuit breaker protection plays a major role as it is used with grounding for the protection of electronic overloading and heat build-up. It is absolutely essential nowadays because the safety mechanism of this equipment fully guards a structure and its occupants against the electrical hazards like faulty wiring, improper grounding, short-circuit, voltage fluctuations, etc.

Circuit breakers require more maintenance to ensure that they are fitted with genuine parts. It is common that the function of circuit breakers is negatively affected when genuine replacement parts are not available that will result in frequent repairs, stoppage time and power failures. Likewise, the durability and longevity of a circuit breaker also depends on the magnitude of the breaking current. Likewise the ideal function of circuit breaker protection is it easily detects a fault condition and by interrupting the continuity it immediately discontinue the electrical flow. A circuit breaker will be reset either manually or automatically to resume normal operation.

Electrical system maintenance and repairs are very important though main considerations are services cost and the availability of genuine replacement parts for corrective maintenance. It gives a direct impact in the life of circuit breakers if replacement parts are available because the outage time will be significantly reduced. There are several safe and effective methods to extend the service life, durability and dependability of circuit breakers using replacements and reconditioning. Adding more some incorporating advanced technology will improve the life expectancy of the circuit breaker and keep it in good shape even beyond its service life.

For more tips on circuit breakers maintenance and repairs, contact ElecComm.

Joseph Coupal - Sunday, April 19, 2020

It is essential that every distribution circuit within a wiring system is protected against overload. A circuit overload occurs when the amount of current flowing through the circuit exceeded the rating of the protective devices. The reason is that all electrical circuits are designed to handle a limited amount of electricity. There is overload when you draw more electricity than a circuit will safely handle. Circuits are made up of a breaker, fuse for old wiring systems, and devices like light fixtures, appliances etc. The electricity usage of each device when running will add up to the total load on the circuit. In case there is no breaker in the circuit, the circuit wiring will overheat which will melt the wire insulation leading to a fire.

First and foremost in preventing electrical circuit overload is to learn the maximum amperage that will be demanded from the circuit. Once you have mapped the basic circuit layout, calculate the safe load rating of each circuit to get the exact value of how many things you will operate on that circuit. Mapping the circuits also will tell if there is a need for new circuits to meet the normal needs. Another protection for electrical units is protecting the actual electrical wires supplying the circuits against an overload that will exceed their carrying capacity. Furthermore, protecting from an overload the individual appliances and electrical equipment connected to a supply circuit. Remember that different circuits have different load ratings such that some circuits will provide more electricity than others.

In order to prevent electrical overloads, circuit breakers and fuses are designed to trip or blow, stopping the flow of current to the overloaded cable. Likewise, overload protection is protection against overheating. It operates at a slow pace. A thermal-magnetic circuit breaker is an example of protection in one device. And while circuit breakers are reliable and doing an excellent job preventing open fire due to overloads, the safest strategy is to manage your electricity consumption to prevent overloads in the first place.

For more electrical safety tips, contact ElecComm.

Joseph Coupal - Sunday, April 12, 2020

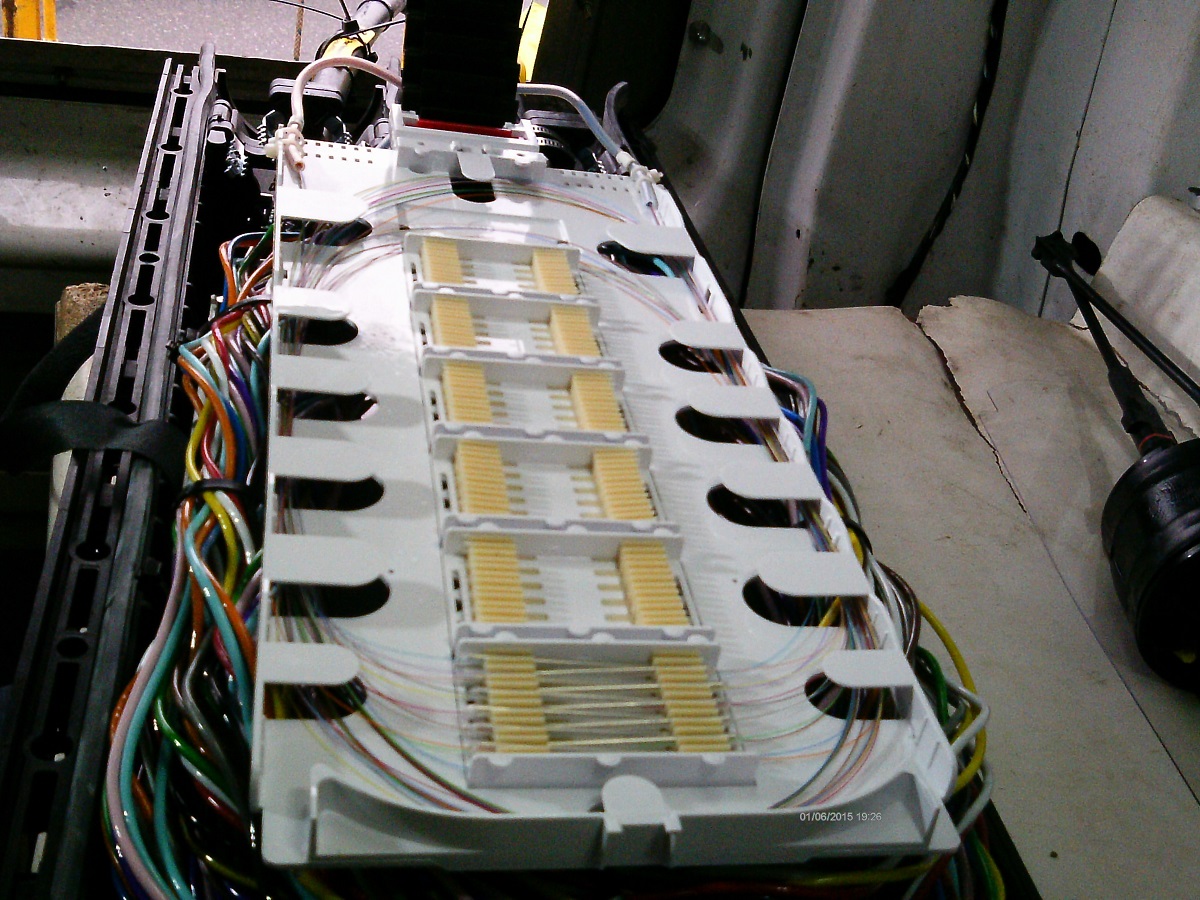

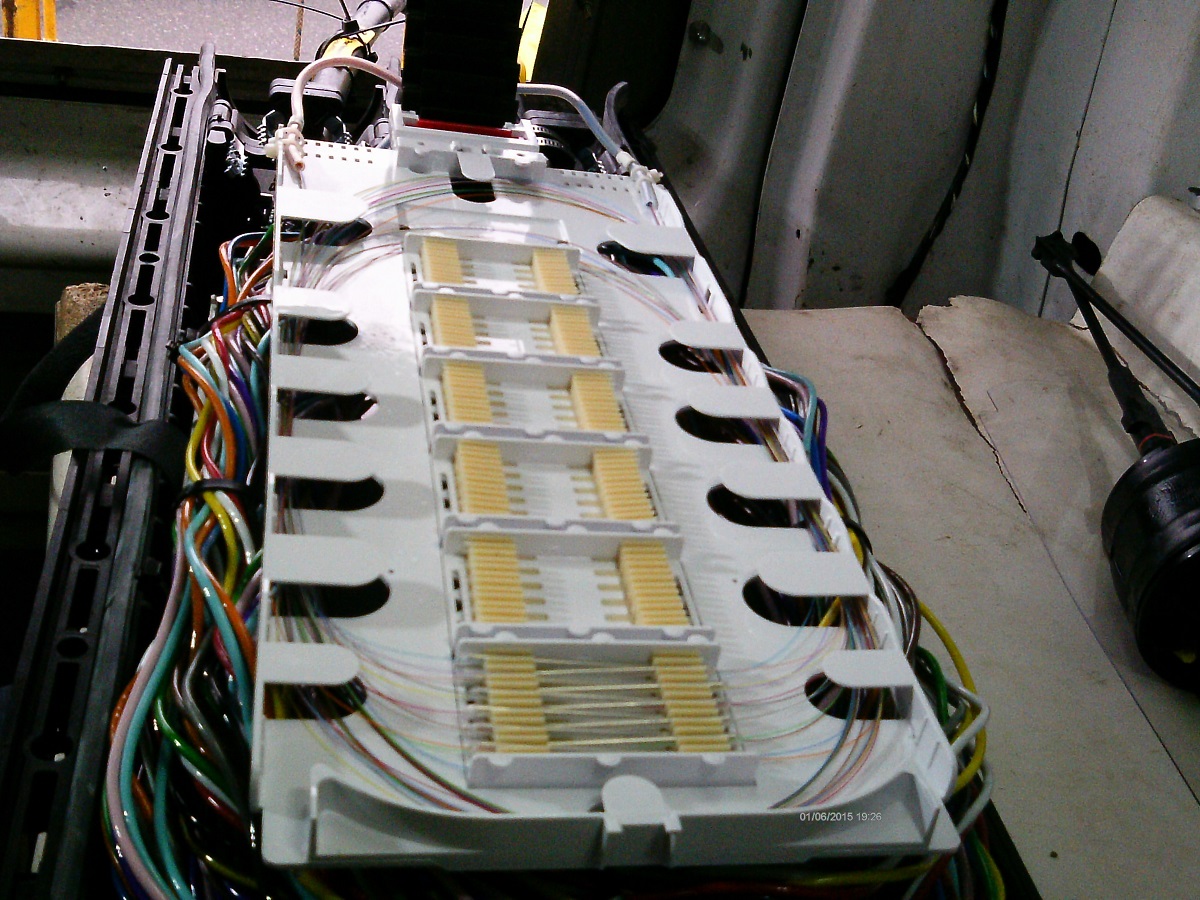

Upgrading obsolete communication networks to fiber optic cables offers a host of advantage. Fiber optic cables have a much greater bandwidth than traditional copper cables therefore they transmit significantly higher data as compared to other transmission means. Here are other reasons to consider a fiber upgrade to your data system:

Minimal Power Loss

Since optical fiber present minimal power loss, data transfer can reach longer distances. In contrast with copper, the only recommended copper distance in a network is 100m whereas optical fiber can go up to 2 km.

Unaffected To Electromagnetic Interference

Optical fiber cables are unaffected to electromagnetic interference. Moreover, it can work in electrically loud settings without issues because electrical noise doesn't seem to influence the fiber.

Greater Capacity

Fiber optic cable has approximately 4.5 times much capacity than copper because wire cables has cross sections that is 30 times short.

In comparison to copper, a fiber optic cable has nearly 4.5 times as much capacity as the wire cable has and a cross sectional area that is 30 times less.

Thinner and Lighter Weight

In terms of weight, optical fibers are thinner and lighter when compared to metal wires. It also take up minimal space with cables of the same data capacity. And Since they are lightweight, fiber optic cables are easier to set-up.

More Secure Data Transmission

Since fiber optics do not radiate electromagnetic energy, the emissions are not intercepted. This makes fiber the most secured means there is for transmitting confidential information as manually tapping it requires lot of skills to perform it undetected.

Flexible

Optical fiber are incredibly flexible with excellent tensile strength. It is also resistant to corrosive factors that easily affect metal wires.

Minimal Cost

Simply, the raw materials for fiber optics are glass which a lot more cheaper than copper.

For more information about fiber optics, call Eleccomm.

Joseph Coupal - Friday, April 10, 2020

Accidents are common with poorly maintained aerial lifts. Lift accidents are caused by faulty outrigger, wobbly guardrails, hydraulic leaks, defective brakes, and a host of other failures. Lift-related accident risk is mitigated dramatically via professional aerial lift routine maintenance service. Here are just a few documented accidents associated with poorly maintained lift equipment:

- Tip-over incidents usually happen when the operator erroneously position the lift. It also takes place when you hit into an immovable object or the machine malfunctions. Ensure that you position the equipment on level ground far from divots, avoid other objects and make sure the equipment is working properly.

- Fall accidents usually happen when a worker bend too much over the guardrail. Most of the time it is due to wrong distance estimation when reaching the next window or cable. To resolve this common incident, operator must be aware of the risk when operating an air lift at excessive heights. Always ascertain to move the aerial platform at the right position. Regular maintenance is required to ascertain your equipment can be properly maneuvered.

- Electrocutions take place when operators run across an overhead cable or power line. Before turning on your engine, check your surrounding for any obstructions above you. Lower the lift when running beneath wires and avoid moving to hazardous areas. Assume all cable wires live.

Moreover, read the manual for your equipment’s horizontal and vertical reach limits. Stay within this limit for safety.

When it’s time for you and your business to bring your lift operations to a documented safe state, seek aerial lift testing services from the Boston-area professionals who’ve been doing this for decades now. Contact ETS Inspection and Testing Services, and let’s get it done!

Joseph Coupal - Tuesday, March 31, 2020

The American National Standards Institute defines the mandatory aerial lift maintenance and repair standards that all lift equipment companies must adhere to. Companies must remain ANSI compliant not only for the purpose of ensuring safety operations but to prevent costly penalties and legal implications as well.

The A92.6 ANSI policy serves as a reference that influences manufacturing and design, rebuilding and reconditioning of all aerial equipment. The guidelines impact not only those who own the equipment, but certainly those who operate, inspect, maintain, and repair the lift equipment.

The annual and frequency inspection directives are listed in the guiding principles and the guidance and emphasis is clear that only certified technicians are to perform these activities. The personnel must be trained and certified in the care of the exact or models of similar function and capability. The inspection must take place at least every 90 days or after 150 hours.

Annual inspections must not exceed 13 months from the date it is previously checked. Plan the scheduled maintenance according to your operation hours and the type of service the aerial lift is employed. ETS can perform this routine upkeep for your machines. You can count on our expert technicians to service your equipment to the most stringent quality standards.

Contact ETS Inspection and Testing Services to help you comply with the regular maintenance of your fleet based on ANSI Standards.

Joseph Coupal - Tuesday, March 31, 2020

With the rising number of residential and commercial properties, the growing number of private and municipal golf courses, the demand for golf-related safety systems such as quality golf course poles and netting solutions are naturally on the rise as well.

Allow us to introduce you to another field of excellence that your trusted partners here at ElecComm provides to the greater Boston area and beyond. Our steel pole and netting systems for driving ranges, golf clubs and fairways across New England are protecting golfers and course owners alike and have been for decades now. Our services include pole & netting design and installation, replacement and protection netting. We customize netting systems according to the location and weather conditions. Contact us for a golf course safety consultation. We’ll gladly discuss with you ball trajectory studies, custom netting designs, installation options, and much more.

For information regarding golf netting installation and maintenance services, contact ElecComm.

Joseph Coupal - Thursday, March 26, 2020

If you are looking for certified professional engineers in Boston to deliver commercial electrical project management, design, and installation of underground high voltage cabling systems, ElecComm is the company Boston has trusted for decades.

Our team of certified engineers can perform and manage construction, splicing, testing, maintenance and restoration of fiber, copper, and hybrid fiber-coax Telco networks across New England. We have laid and spliced thousands of miles of cable up to 35,000 volts. We are one of the largest electrical and communications line construction companies in New England. We deliver immediate 24/7 emergency and routine service response.

ElecComm's core business focus is on the installation, removal, and maintenance of overhead and underground electric/communications distribution systems. Contact ElecComm for any overhead and underground cabling system concerns or to learn more about our other services.

Joseph Coupal - Thursday, March 19, 2020

In light of the COVID-19 crisis, we at ElecComm continue to provide service to our customers. However, we made some adjustments to our operations in order to reduce the risk of spreading coronavirus. This includes postponing elective maintenance work and repairs and temporarily closing our office to walk-in customers at least through April or until further notice.

We assure you that none of the operational changes being implemented will cause disruption of electric and telecommunication service to customers.

Moreover, we are postponing projects that would demand power outages, except when it is deemed important to safety or reliability. Our team of technicians will carry on with essential tasks that require minimal public interaction such as the trimming of trees to minimize potential outages, replacing essential equipment and system resilience tasks that can't be delayed.

Emergency outage restoration remains a top priority especially when the situation hampers public safety.

Furthermore, we are trying to reduce the number of personnel in the field so as to protect our employees and the public from contracting the virus.

Contact ElecComm for service updates and concerns.

Joseph Coupal - Friday, March 13, 2020

Those in the electrical power work year-round to ensure the uninterrupted supply of power that civilized society not only expects but demands to stay functional. Our storm response teams are normally challenged to the highest extent during the winter storm season, but as we move into spring and summer, new challenges from mother nature’s severe thunderstorms are just around the corner.

Severe thunderstorms devastate electric line poles and infrastructure and will interrupt the electrical supply chain. Our storm response service teams are trained, equipped, and ready to respond to any electrical emergencies that transpire. Those within the electrical service industry across the greater Boston area know us as the region’s number one choice for the inspection and testing of essential electrical equipment , but know that our ETS technicians are ready to deploy storm response teams on a moment’s notice. We manage an entire of emergency responders complete with a specially configured fleet of vehicles on 24/7 standby.

Contact ETS Inspection and Testing Service when you require storm service support.

Darren Kincaid - Thursday, March 12, 2020

Electrical distribution is something that intimidates many people and actually this is probably a good thing. The more we respect electrical power, how it is distributed, and how it is protected the safer we all are. Electrical distribution boards can be a mystery, and today we hope to educate you all on this very subject.

The electrical distribution board houses all the circuit breakers, earth leakage units, doorbells and timers. The distribution board ensures that electrical supply is evenly distributed in the building. Its main purpose is to keep the building and its people safe. While installing an electrical distribution board, it is the “home plate” for the safety mechanisms that keep you, your family, and your business safe. The entire supply of electrical power comes from the network to the building which is all connected via an electrical distribution board.

Distribution boards are versatile by design. You may have multiple electrical distribution boards for various parts of your building. They will be controlled by a switch disconnector. It is necessary that it has sufficient space for other wires, fixtures and cable, considering it is very easy to install as long as it is not close to any water splashes.

Further, an electrical distribution board varies depending on the structural and technical aspects on each area and its electrical requirements. It is normally purchased as empty enclosures, a ready-to-use wired standard unit or something specially manufactured and designed on the user’s requirement. It is important to invest in the necessary components which an electrical distribution board is licensed to have a fuse link, a bus bar, a residual current detector and bypass equipment. This is for protection against shock or fire and the residual current detector is required.

To learn more about electrical distribution, contact ElecComm.

Joseph Coupal - Saturday, February 29, 2020

In business, big and small, power cabling is an important element of plant infrastructure. Power Cables, like any mechanical device, require protection and maintenance. It is very important to be cognizant and knowledgeable of the most common causes of power line failure. Today we hope you by learning here that you make you and your business safer and more profitable.

Almost all utilities and large industrial facilities have thorough systems of power cables. Many of these cable systems are ageing and failures are becoming common. Check your records and find out when the last time your power infrastructure was assessed for functional viability. Professional power and communications line installation and maintenance firms such as ElecComm are trained and equipped to sniff out threats to your personnel and equipment that most never see until it is too late.

Aged lines are a danger. The ageing process usually results in weakening, cracking and eventual failure of the insulating and sheathing materials. Exposing these conductors introduces the likelihood of short circuit that can result in electrocution or electrical fire. In order to ensure fault-free operation of power cable it is important to undergo a thorough study of the type of faults and their location. The cable will be traced, corrected, or replaced.

As it pertains to power line installation and maintenance across the greater Boston area, trust the power line maintenance, repair, and upgrade professionals at ElecComm. Contact us ElecComm anytime.

Darren Kincaid - Thursday, February 27, 2020

Dielectric Testing and Inspection is something smart business owners build into their annual operations plans. This safety and operational readiness program not only assure that your aerial devices are safe to operate but they also ensure operational readiness is maximized. We don’t need to explain to you the complex technical nature of your aerial device equipment. We also don’t need to tell you the consequence of poor maintenance practices and the high cost of equipment repair. Prevention is the key to profitable business operations.

ETS Inc. is Boston’s trusted dielectric testing and inspection service provider for aerial lift trucks and digger derricks. Our technicians are highly trained certified professionals who view your and your staff’s personal safety as a professional calling of the highest order. It’s not just about OSHA and ANSI protocols. It’s about taking care of you and your business.

Whether you need a single aerial device tested and certified or need help developing an operational test and evaluation program to govern an entire fleet, we’re there for you. Contact Boston’s most trusted support provider. Contact ETS.

Joseph Coupal - Sunday, February 23, 2020

Whether you are managing the upgrade of your growing business power infrastructure, laying down new cable for a public utility, or addressing sudden or recurring electrical problems, we want you to know that ElecComm’s core business focus is on the installation, removal, and maintenance of overhead and underground electric and communication distribution systems.

We want you and your business to operate in a safe and as profitable manner as possible. You should always qualify your electrical service provider for experience and trust. When you see overheat cables exposed and are threatened to come into contact with personnel or equipment, that is an issue for immediate correction.

We thought we share some common characteristics of power cables:

- Should you need new cables, copper is your leading choice. Copper is safe and does not get heated and easy to joint and transmit power efficiently with no loss compared to Aluminum conductor. Copper has an excellent conductivity, flexibility and tensile strength among other characteristics.

- The cable current capacity is affected by a range of different factors and does not always remain stable.

- A cable armor is made up of steel tape or steel wire and is very useful as it gives mechanical protection and also works as a fault current carrying path.

Always consider the overall safety of the electric cabling that you manage or have installed. Faulty installation will lead to service failure and/or accidents. Hence, before carrying out any electrical installation project, contact ElecComm, your trusted source for all things related to electrical and communication cabling.

Joseph Coupal - Monday, February 17, 2020

ElecComm specializes in the installation and maintenance of underground electrical cables in and around the greater Boston area. The demand for underground power solutions continues to rise as they are proven to be the best value for both public and private business entities. The key benefit of course is the protected nature of the high -voltage assets.

Maintaining and troubleshooting requirements are drastically reduced as compared to overhead cabling implementations, but when the time comes for repair and maintenance were there for you as well. We are highly trained and equipped with the advanced techniques and tools to maintain, fix, and expand your high-voltage power systems.

We’ve been taking care of Boston’s high voltage power requirements for decades now. Go with those you know you can trust to deliver reliable and valued high-voltage electrical services. Contact ElecComm.

Joseph Coupal - Wednesday, February 12, 2020

Electrical linemen is by nature one of the most dangerous occupations. They regularly put their lives at risk as they service live lines daily. Ensuring that all safety tools such as hot sticks work at optimal performance is crucial. To ensure this, regular and recurring dielectric testing service must be accomplished to protect both staff and electrical resources.

Are your hot sticks scratched or do they have a dull finish? Such conditions indicate that the stick is possibly unable to repel water and introduces a dangerous environment. That device could conduct current. You might be conducting dangerous business operations without even knowing it.

ETS Inspection and Testing Service offers full testing and hot stick repair service to ensure hot line tools are safe to use and perform optimally. These tools include Hot Line Stick equipment, Pruners, Fuse Pullers, etc. They are dielectrically tested for defects and malfunctions. The sticks are temporarily removed from the service to send it for repair and refinishing. After it is restored, it is once again tested dielectrically to evaluate its performance as it needs to pass the standards.

Certified technicians will diagnose the issue, find out the root cause, perform a comprehensive maintenance check and provide the quote. Mechanical defects, scratches, and cracks are then repaired. Refinishing process is done to return the tool to its original condition. It will undergo another dielectric test to ensure it passes the safety and performance standard. The tools are continued to be cleaned and maintained when it is returned to the field.

For more information about servicing, maintaining, and testing your hot sticks, contact ETS Inspection and Services.

Joseph Coupal - Monday, February 10, 2020

In any cable laying installation, protecting the wire becomes the utmost consideration. There must be thorough planning on bedding the cable in order to avoid subjecting the cable to damage and the potentially deadly consequences surrounding damaged power cables.

One of our business core competencies is underground cable installation and maintenance services and we've done it for decades now. We employ highly trained and experienced technicians who are armed with highly specialized equipment to locate existing or paint optimal routes for new cable lay down.

Again, we specialize in high-voltage cable installation and maintenance. For more information on underground cable services, contact ElecComm.

Joseph Coupal - Tuesday, January 28, 2020

In assessing the safety of your office, site, or plant’s safety of electrical operations, we thought we’d give you the background that each and every member of our team here at ElecComm carries in to serve you.

Every ElecComm electrical worker carries all regulatory certifications. But in addition, our underground employees receive a comprehensive additional OJT training regimen that includes: Heat Shrink Construction

- Cold Shrink Construction

- Pre-Molded Construction: Both 200amp & 600amp

- Cable Theory

- Tools & new Technology

- Transformer Theory

- Live Secondary connections and Cutover’s

Our overhead electrical technicians also receive training well above regulatory mandated training. That training includes hurt man rescue, climbing gaffs and bucket rescue, and a host of others.

We invite you to view ElecComm’s safety, health, and Training webpage so you have an idea who is trained, ready, and available to address all of your commercial electric needs. For more information about our comprehensive electrical services, contact ElecComm.

Joseph Coupal - Monday, January 27, 2020

If your business involves hydraulic equipment, cylinder repair and maintenance is likely a significant element of your operating budget. When that hydraulic equipment fails due to neglect, you can bet an unacceptably high hit will besiege your business due to operational downtime. Don’t let that happen.

A large percent of mechanical equipment failures is due to design failures. This means we can expect that there are hydraulic cylinders that are not exactly engineered for the purpose they're operating in. Although this doesn’t necessarily mean that hydraulic equipment failure is immanent, it certainly will shorten the expected life cycle.

So, here are things to look for and to conclude from your hydraulic cylinder inspections:

1. Rods That Are Bent or Deformed

This is usually caused by:

- inadequate rod diameter or material strength

- incorrect cylinder mounting arrangement

- When cylinders are deformed or bent, deforming load is put on the rod-seal. This leads to leakage and premature seal failure.

2. Rod Finish

The cylinder rod's surface finish has an important impact on the rod seal's life. When it is to smooth, its seal life will be reduced because of scant lubrication. When it is too rough, it will increase contaminant infiltration and an intolerable leakage level beyond the rod seal may rise.

In order to extend cylinder service life, keep the cylinder rod's surface greased, early and often. For some applications, shroud or bellow installation can protect the rod surface and its seals from damage impact and contaminants, can provide comparable life extension advantages.

3. Inflated Cylinder Tubes

Insufficient wall thickness and material strength for the cylinder's operating pressure can result ballooning of the cylinder tube. When the tub balloons, the accurate tolerance between the piston seal and tube wall disappears, enabling high-pressure fluid to bypass the seal. This high velocity fluid can wear the seal and confined heating as a result of pressure drop across the piston decreases seal life. Premature failure of the piston seal can result.

4. Inappropriate Bearing Area

When bearing bands in the gland on the piston are inadequate to support the side thrust moved to the cylinder, the rod and piston seals are burdened with excessive load. This will result in deformed seals and premature failure.

For more tips on hydraulic repair and maintenance, contact ETS Inspection and Testing Services.

Joseph Coupal - Tuesday, January 21, 2020

Electrical equipment, especially high voltage cables must comply with electrical technical and safety specifications. There is a standard operating procedure that we employ here at ElecComm to identify and repair electrical hazards. Of course, we are here to consult you on best practices to control risk within any/all of your electrical service endeavors.

ElecComm's core business focus is the installation, removal and maintenance of overhead and underground electric/communications distribution systems. If you even suspect that any power distribution element of your business has not been properly inspected and maintained, your next call should be to us.

We’re here for you and your as it pertains to all thing’s electricity. Contact ElecComm today.

Joseph Coupal - Friday, January 17, 2020

Businesses today are rapidly changing out obsolete copper transmission wire with fiber optic cabling. The advantages of fiber optic cable over copper are stark. Today, we’ll share with you some of the many advantages of fiber optic transmission over electrical transmission systems:

- Exceptional High Bandwidth - Currently, no other alternative transmission medium exceeds the performance of fiber in terms of bandwidth. Fiber optic cables can transmit significantly higher volume of data per unit time. Far greater than copper cables.

- Signal Travels Longer Distance - Signals can reach longer distances over copper cables since optical cables have low signal loss.

- Defiance to Electromagnetic Interference - Fiber cables have an extremely low rate of bit error (10 EXP-13). Fiber is quite resistant to electromagnetic interference.

- Low Security Risk - What commonly drives business operators to upgrade to fiber-optic communication is their concern for data security. Since the signals are transmitted through light, it is comparatively difficult to intercept.

- Small Diameter - With fiber optic cables' smaller diameter, they can have more space in fiber optic transmission.

- Light Weight - Since they are composed of glass or plastic, they are thinner, lighter, and convenient to install.

- Capacity to Cater Increasing Bandwidth - It has the ability to accommodate additional equipment to an existing cable system because it can provide immense capacity than the primary cable setup.

We install and maintain fiber optic networks across the greater Boston area. To learn more about our services, contact ElecComm.

Joseph Coupal - Friday, January 10, 2020

High voltage power cables are inherently dangerous in nature and not something anyone should take lightly when operating on or around them. The warning signs on your property with large wires and cables stock should be strictly enforced. So now let’s discuss what you, the business owner, must take into account when you or your staff must directly engage high voltage cables or equipment in their near vicinity.

Any high voltage power cable must adhere to established safety standards. For overhead power lines, it is recommended to research and enforce defined separation distances that non-trained personnel can approach. It is advisable not to allow any type of labor activity close to overhead power lines. Never allow unqualified staff or customers to enter an electrical power substation or other marked areas.

It is crucial to ensure that the high voltage power cable are manufactured with the highest quality line possible. Purchase and install the correct high voltage power cable that is durable enough to withstand the power demand and environmental challenges presented.

As previously stated, but worthy of emphasizing again, it is critically important that all employees should be trained and certified on the equipment that they are to work on. Conduct an initial Workplace Risk Assessment prior to starting work and periodically update and re-execute that plan.

High voltage work and safety consultation is what we do. For more information on the subject of high voltage cables, contact ElecComm.

Joseph Coupal - Thursday, January 09, 2020

Annual inspection of Digger Derricks and Aerial Devices are essential acts not only to adhere to OSHA or ANSI requirements but to ensure the equipment is safe to use. A thorough inspection must be applied to all system components of the device. Although user manuals specify the components to be checked, a certified technician with adequate training, knowledge, and competitive experience is essential to ensure a comprehensive inspection.

If you're an owner and you choose to perform you own annual inspections, just know that you are likely to miss or overlook critical items that professional inspectors are trained to focus upon. Here is some list of most frequently overlooked items:

Overlooking Safety/Operational Labels

Operational and Safety labels provide significant details to users. The decals attached to the equipment might be damaged or removed from power washing over time. You are likely to miss a component if the decals are no longer in place. Hand signal charts must not be omitted from digger derricks. They provide an important function in the communication between operator and ground personnel, especially in a loud setting. Potential injury or damage in equipment is imminent if there's a failure to convey directions clearly.

Poorly Maintained Hydraulic Oil Levels and Hydraulic Filters Are Not Replaced

Hydraulic oil levels must be maintained based on the manufacturer's recommendation in order for the equipment to run seamlessly. If it reaches a low level but left unattended, it could lead to untimely costly repairs. It could initially cost you $2,000 repair for burning up one pump. Aside from that, you should also consider the deficit due to the equipment being removed from service.

Meanwhile, you should not check the fill levels when the outriggers are extended for it can concur to overfilling. When the system is overfilled, the space is no longer enough for expansion. This can add up to oil leakage. Moreover, a dirty oil filter can expedite the deterioration of the key components including pumps, hydraulic valves, cylinders, and hoses. This is because the filter is no longer efficient in trapping debris and contaminants prevalent in the fluid.

Defective Winch Rope

The winch rope should also be unwound and checked by hand at the yearly inspection. If you notice cuts or feel a bulge, this indicates an internal rope damage which is an outcome of shock loading or kinking. This means the rope must be replaced. Rope manufacturers provide more scrutiny and replacement conditions.

Torqued Rotation Bearing Bolts

This is an important item in the inspection list that should not be missed. Two personnel must do the checking so one may rotate the bearing while the other one inspects the bolt torque. Proper bolt torque and greasing must be done. Otherwise, it could result in failure of bearing bolt because the rest of the fasteners are overloaded. Repairs related to bearing failure could cost you up to $10,000.

Bearing Deflection/Backlash Has Too Much Allowance

Inspecting the allowance in the rotation bearing takes a while to master and requires clear insight on how to measure it. Too much allowance could indicate rotation bearing is worn and requires replacement. Furthermore, it may also hint that the boom has been shock loaded.

Leveling Chain Is Too Loose

Aerial devices' leveling chain must have precise amounts of preload. Potential wear and tear can increase when there's too much or too little tension. Inspecting the leveling tension needs removing off the boom lid. When the chain is not kept within tolerance, it may impact the self-leveling of the bucket when the booms motion through their range of motion.

Bucket and Liner Wear and Tear

The structural integrity of the bucket is damaged when there are cracks and distortions noted. A damaged liner can add up to the diminishing dielectric strength. Most of the time, inspectors fail to take off the liner when checking the bucket. Tools can drop and damage the liner, even the bucket. So make sure to check inside and outside the bucket and include underneath it.

Although carrying out the task on your own may appear as an affordable option, it is highly recommended to seek certified technicians who are experts in this field. If you are looking for a certified company who can conduct dielectric testing and inspection, contact ETS Inspection and Testing Services.

Joseph Coupal - Tuesday, December 31, 2019

Hello from Boston’s number one choice for underground cable installation services. We offer this blog as an educational service with a goal of helping you and your business be a more safe and profitable enterprise. High-voltage cabling installation and maintenance if a very dangerous endeavor and we’re here today to share some lessons learned.

The value of knowledge and experience in this industry must never be taken for granted. When underground cables are damaged they pose a life and death situation. Precautionary measures must be strictly followed in order to avoid the potential fatal threats of shock, explosion, and fire. We are well versed in all precautionary measures having served in this industry for decades.

Underground electrical cables are hazardous to the unaware because they look like pipes. To the untrained eye, they are very hard to distinguish from ordinary cables. A knowledgeable and experienced underground cable professional is fundamentally important to assessing the underground high voltage situation and directing the initial response. We can and will do that for you.

There are many considerations to take when laying high-voltage underground cables. When laying cable, the depth of cable must comply to varying local codes. You must take proactive measure to prevent moisture accumulation. Prior to excavation, risk assessment must be strictly accomplished to prepare and eliminate risks before work commences. Careful planning is essential before the work starts.

Risk assessments will factor into how the work is to be carried out. For instance, when multiple cables are placed in the same slot, horizontal or vertical spacing is required to reduce the effect of mutual heating. The space between cables also ensures that the failure of the cable will not damage adjacent cables.

There is so much to consider and we want you to know that the professionals here at ElecComm are ready to assist. For more information regarding high-voltage underground cable installation and maintenance services, contact ElecComm.

Joseph Coupal - Monday, December 23, 2019

Christmas and Chanukah share a similar spiritual message: that it is possible to bring light and hope into the world. These two holidays occur together this year, which makes this an even more special holiday season.

This is a season to reflect upon how fortunate we are to have you as our customers: our friends and neighbors. During these holidays, we wish you, your family, and your friends a safe, joy-filled, and relaxing season.

Warm wishes for a Happy Hanukkah, a Merry Christmas, and a most Happy New Year! With peace, joy, and love this holiday season and beyond!

Joseph Coupal - Friday, December 20, 2019

Christmas and Chanukah share a similar spiritual message: that it is possible to bring light and hope into the world. These two holidays occur together this year, which makes this an even more special holiday season.

This is a season to reflect upon how fortunate we are to have you as our customers: our friends and neighbors. During these holidays, we wish you, your family, and your friends a safe, joy-filled, and relaxing season.

Warm wishes for a Happy Hanukkah, a Merry Christmas, and a most Happy New Year! With peace, joy, and love this holiday season and beyond!

Joseph Coupal - Tuesday, December 17, 2019

Everyone needs to understand and appreciate the danger of downed power lines. This safety issue is more common than people think. Power outages and downed lines are inevitable when winter storms occur. Downed power lines can be deadly to not only those who come into direct contact but also to those merely in close proximity as well. If you found a downed power cable, do the following:

- Report it immediately to the local authorities or electric company. Stay at least 35 feet away from a downed live cable.

- Do not clear snow, ice or storm debris. Wait until the power is disconnected or power lines are repaired.

- In case a power cable lands on your car while you are inside, stay inside the vehicle until emergency responders arrive. At any cost, do not attempt to get outside the car for this is extremely dangerous. Likewise, do not attempt to help other people with the same aforementioned situation.

- If you find a power line in contact with your vehicle before you enter, stay away from the vehicle, and call the authorities and/or the local utility company. Contact ElecComm in situations like this or if you need quick power line repairs.

Joseph Coupal - Tuesday, December 10, 2019

Power outages are a common occurrence during winter and they will occur without notice. Power outages can be one of the most damaging events that a business owner can face. It pays to be prepared for contingencies such as power outages. Prepare your facility and your business by taking the following steps:

Ready an Emergency Kit

Make sure to have an emergency kit that contains a first aid kit, flashlight with extra batteries, blankets. Place it somewhere readily accessible. List important phone numbers especially your power line support team. Notify them of your power issue as soon as possible. Have a copy of your office floor plan which shows the emergency exits of the building and location of gas and water shutoff valves.

Create a Contingency Plan

Contingency plans will help ensure that your business will stay up and running even while responding and recovering from emergency situations.

Train Employees

Make sure everyone in your office knows how to appropriately respond to a power outage. This will ensure their safety as well as customers that are caught up inside the building when the power outage happens. Make practice drills with your staff a routine. This way you can see areas where you need to improve and adjust before the disaster strikes.

Get Power Surge Protectors

Power surge may happen when the electricity turns back on. This can cause damage, sometimes irreversible to important electronic equipment. Having a surge protector will prevent excessive outflow of energy to keep devices safe. If investing in surge protectors is not a viable option, you can just turn off all equipment during the outage to prevent energy surge when the electricity is back on the grid.

Install Fire Detectors

Power surge can also cause electrical fires once power is back on. In order to prevent flames and protect your facility from costly damage, install fire detectors and sprinkler system.

Have a Backup Generator In Place

Consider investing or renting a backup generator for alternate source of power. This will keep your facility up and running even if the utility power restoration will take a long time to get restored.

Lastly, if you need power line repairs and maintenance, contact ElecComm.

Joseph Coupal - Tuesday, December 10, 2019

For years we’ve served the greater Boston area with professional hydraulic preventative maintenance and repair services. Today’s blog post is our way of giving back by sharing our professional knowledge with you to help ensure your business continues uninterrupted and unthreatened by hydraulic cylinder failure. With that said, if they ever do we can immediately respond to provide you with cylinder repair service.

Here are things you must do to protect your hydraulic systems:

1. Keep Hydraulic Seals Intact and Leak-Proof

In order for the cylinder to function optimally, a steady supply of pressurized liquid inside the cylinder is essential. Seals must remain intact to keep the link between the cylinder and the moving rod leak-proof. If the seals are damaged, fluid will leak and will result to diminished force.

Taking extra care to the hydraulic seals will avoid seal leakage issues. Regular visual inspection must be done to check for any signs of wear. When placing hydraulic seals do it with caution in order to ascertain they don't get damaged before installation. Handle seal replacements with care. Incorrect setup will undermine the seal integrity and will lead to leakage over time.

2. Keep Fluid From Being Contaminated

In addition to maintaining a sufficient supply of hydraulic fluid, clean fluid is essential to keep the system's top performance. Old or contaminated fluid will cause damage to the mechanical systems of your heavy equipment.

One common type of hydraulic fluid contamination is moisture. To prevent moisture contamination, use airtight barrels when storing fluid reserves to protect it from solar exposure and temperature variations. This avoids breathing, a phenomenon wherein the water permeates the barrels when they expand and contract. Make sure to only open fluid container in a clean area, flush out the hydraulic system properly prior to adding a new fluid. Doing these measures will prevent fluid contamination, and the potential issues associated with a contaminated hydraulic fluid.

3. Maintain Your Rods – Keep Them Straight

A bent rod can result to eventually result to cylinder failure. The rod can be bent when load weight is moving greater than the force produced by the pressurized fluid within the cylinder.

Bent rods will cause scrapes against the cylinder's inner walls, making it more prone to corrosion. Rod seals may also be susceptible to damage due to bent rods.

In order to accurately test the straightness of the hydraulic rods, a dial gauge is used. A rod that goes beyond the admissible straightness standard should be fixed using a press or replacement might be necessary to maintain the hydraulic cylinder's integrity.

The condition of your hydraulic cylinders set in your heavy equipment can greatly affect their performance. Thus, it is important to prevent cylinder failure at all costs. Being proactive is the key in preventing cylinder issues by taking note of the aforementioned tips.

When you need hydraulic repairs and services in Boston, MA, contact ETS Inspection and Testing Services.

Joseph Coupal - Thursday, November 28, 2019

The winter weather poses the greatest threats to the power line infrastructures. Extreme cold can and will disable power line systems especially those that are obsolete or with failing insulation systems. Extended power outages are inevitable. Downed power line repair service is a core competency of ElecComm and we stand ready to roll immediately upon your call.

Overhead power lines are prone to damage when exposed to violent natural elements such as strong wind, snow, and ice. Severe winter storms break cables and wires with or without the help of downed trees and limbs. Fortunately, our power line response team is staffed, equipped, and ready to take immediate action to get your customers back on line.

As a severe weather contingency plan, it is recommended that insulation of overhead power lines be reinforced to prevent avoidable system breakdowns. We can deliver regular maintenance and repairs for your power lines and ensure that your electrical infrastructure is in top condition at all times and in the best possible position to deliver uninterrupted service.

When seeking power line repair and maintenance services, contact ElecComm.

Joseph Coupal - Monday, November 25, 2019

Thanksgiving Day is the perfect time to remind one another of the many reasons there are to be grateful. We gather on this day to be thankful for what we have, for the family we love, the friends we cherish, the success we have had, and for the blessings that will come.

Thanksgiving is more than the festivities, it gives us time to ponder the lessons that we have learned and how we can spread happiness around, to look back at all the great memories and good people who came into our lives. We appreciate you, our customers and clients, so much.

At this time of year our thoughts turn gratefully to you with warm appreciation. Our best wishes for a Happy Thanksgiving.

Joseph Coupal - Monday, November 25, 2019

Thanksgiving Day is the perfect time to remind one another of the many reasons there are to be grateful. We gather on this day to be thankful for what we have, for the family we love, the friends we cherish, the success we have had, and for the blessings that will come.

Thanksgiving is more than the festivities, it gives us time to ponder the lessons that we have learned and how we can spread happiness around, to look back at all the great memories and good people who came into our lives. We appreciate you, our customers and clients, so much.

At this time of year our thoughts turn gratefully to you with warm appreciation. Our best wishes for a Happy Thanksgiving.

Joseph Coupal - Thursday, November 14, 2019

Everything around us uses electricity. From personal use of power to the heating, cooling and lighting our homes to everything we do in our daily lives we depend on electricity. It operates the countless physical and information chain sources that lead to all the services maintaining public safety and ensure national security. Hardly we realized what if there are some faults and outages that will hinder the functioning of the power distribution?

Underground high voltage lines are ElecComm’s core business focus. We specialize in the installation, removal, and maintenance underground high and low voltage cables. Underground power applications are used where it is impossible and dangerous to use the overhead lines. We commonly install underground power lines in heavily populated areas, in factories, and even while supplying power from the overhead posts to the individual end-user. The space is the top consideration to install the underground networks. It can be impossible to channel through the rocks, or rivers and other waterbeds.

Many do not understand that underground power lines are the more economical solution in the long run. When installed in areas with high population, they do not require any right-of-way take-over. Overhead lines, however, often require right way permits in order to support facilities like towers, poles and etc. It is a big task to remove barriers for electrical clearances in the line path. It is the reason why delays and interruptions are encountered in the process.

Another great impact of underground high voltage lines is preserving the natural beauty and land value of the environment. Since the lines are underground, it does not affect or change the look of the community, scenic areas and historical sites normally preserved. It has an enormous impact in conserving the surroundings.

Moreover, underground high voltage lines installed underground has very minimal effect on climate conditions. The underground line system being reliable and dependable can handle even in times of extreme conditions such as flood, hurricanes, and other natural disasters. Underground lines may not be prone to damages caused by strong winds, falling trees, and other calamities. Whatever adversities may happen, underground transmission is a dependable solution.

Corrective and preventive maintenance of underground cables is vital. In order to ensure the reliability and safety of power distribution system, continuous maintenance must be carried out annually. Frequency of cable faults and damages can be avoided and minimized. It is a normal thing to encounter faults and outages but repairs can be challenging. Recently with modern fault locating technologies, the process of locating the underground cable faults is now efficiently handled.

For more information regarding underground high voltage cable installation and maintenance services, contact Eleccomm.

Joseph Coupal - Tuesday, November 12, 2019

The life expectancy of electrical hot stick varies. At any point, it may fail depending on the use. But some hot sticks can stay in perfect condition for years if they are well-maintained and are not abused. There are several situations that can cut short the life of a hot stick like when they are accidentally dropped from a significant height, but there are also a number of ways to extend its life and service.

Regular Cleaning

Cleaning the hot stick serves one or two purposes that both ensures safety of the linemen using it. Cleaning is a way to eliminate contamination from the surface which could cause an electrical tracking. Doing this also protects its finish while maintaining its hydrophobic qualities. Silicone impregnated wiping cloths or disposable Silicone Wipes must be used in daily basis for cleaning. It can keep the finish of the hotstick intact. While, Moisture Eater II wipes are used for heavier contamination as it removes both dirt and moisture from the surface.

Visual Inspection

It's a protocol to perform a visual inspection to the device prior to use. This practice should include checking its proper functioning while searching for any damages, missing parts or loose components, worn out finish, cracks, scratches and fissures or any electrical tracking evidence. If you suspect a damage to the device, remove it from service immediately.

Handling and Care

Stands or tarps are used to keep the hot sticks from touching the ground of mud and dirt. Handle it with care and avoid dropping it for impacts could lead to defects. A special protective tubes, bags or racks are designed to secure hotsticks during storage and transport.

Testing

Electrical testing of hot sticks must be done at least once every two years and every time there's an uncertainty to the insulation properties of the hotstick. Frequent periodic testing may be necessary depending on its work condition, level of care and frequency of use. It must be done as well after repairs have been made. A worn out finish can erroneously pass the test when you apply sufficient amount of silicone to its surface. It's important to check it thoroughly. In case it fails the the testing, it must not be used for service until proper repairs are made. Certified technicians must assess the issue, do the necessary repairs, and the hotstick must be subjected again for testing before it can be used again.

Repairing and Refinishing

A minor damage or slightly worn surface can still be repaired to extend its service life. The defective components can be replaced, sustained scrapes and scratches on the surface can fixed. Only a qualified personnel should perform the repairs. Since its the linemen's safety that is at stake here, careful attention should be rendered to these protocols. Doing this can also help extend the service life of the hot stick device.

Contact ETS Inspection and Testing Services for hot stick testing and repairs.

Joseph Coupal - Thursday, November 07, 2019

With the growing demand for electrical power, the electrical industry is facing new challenges. Increasing governmental regulation results in electrical service providers operating within increasingly restrictive operational conditions. There is direct and indirect pressure on power utilities to lower the impact on the environment. As a result, underground cable systems are becoming the power distribution system installation method of choice.

The use of underground cables protects the lines and reduces outages, interruptions while simultaneously minimizing maintenance costs. Generally, transmission losses are low with the use of underground cables compared to overhead lines. The new underground cable arrangement with its exclusive features enables an enormous increase in power transmission capacity.

Corrective maintenance is a practice that can’t be ignored. We excel in the installation, maintenance, and testing of underground high-voltage cables. For more information contact ElecComm.

Joseph Coupal - Thursday, October 31, 2019

State and local municipalities alike increasingly turn to underground high voltage cable system due to the strategic long-term value versus above-ground alternatives. Above ground power service interruptions are most often associated with downed trees and other severe weather causes, but it is simple exposure to the elements that ultimately weakens the infrastructure and serves as the cause for excessive maintenance cost.

We’ve provided the greater Boston and surrounding area with underground cabling system for years now. We empower you to deliver more stable and reliable power for the thousands of customers that you serve. Our services also empowers you to save hugely on operations and maintenance expense over time. To find out more about underground cabling system installation, contact EleCcomm.

Joseph Coupal - Thursday, October 24, 2019

Older buildings with ageing (and often) dangerously inadequate electrical systems are exceptionally prone to failure during winter and especially during winter storms. When temperature dips, the exceptional demand on the aging electrical components often surpass the ability to safely operate. Winter storm conditions stress even modern electrical systems.

Extreme temperatures cause deceleration to the mobile parts of an electrical system which makes them more difficult to monitor and control. For example, old circuit breakers that are designed to provide critical safety service can be slow to respond. It is fundamentally important to replace old electrical infrastructure and improve electrical insulation design as a preparation for winter weather.

Contact ElecComm to protect your business plant, property, equipment, and staff. In any storm-related power emergency know that we are ready to respond on moments notice.

Joseph Coupal - Wednesday, October 23, 2019

Winter can be brutal in New England. Make sure your electrical utility fleet is prepared for both the expected and the worst-case scenario during this winter season. A winter preparedness plan is vital and it includes regular servicing of your fleet equipment. ETS Inspection and Testing Services here in Boston will ensure that your fleet services is as prepared to serve uninterrupted this winter season.

We travel across New England to test and certify equipment. We also employ the use of our large warehouse should you be better served by on-site maintenance services. We service the widest range of electrical utility equipment to include aerial devices, digger derricks, cranes and support equipment. Most of our clients enjoy the use of scheduled recurring fleet maintenance and servicing. This provides the business owner with the very best operational readiness level possible.

Regular fleet maintenance ensures the safety of both your crew, your equipment, and everything that they service. When it’s time to schedule your next fleet maintenance and repair service, contact ETS Inspection and Testing Services.

Joseph Coupal - Friday, October 18, 2019